Special Solutions for Printing

Experts for Special Printing Solutions

Product Area HYCON

In the HYCON product area we bundle our many years of experience in thick film technology. With special machines developed for the screen printing process,

we can implement any special printing solution with you. We apply different paste systems on the most diverse substrates with highest precision.

Would you like to print on special materials such as ceramics, foil, textiles, metals or silicon? Or do round or curved surfaces have to be processed?

We will work with you to develop the right solution for your application – from paste selection to production line.

Because our competence does not only refer to the printing process, we also develop handling and drying solutions for your requirements.

In addition to classic screen printing processes, we also use screen printing technology to produce complex, high-precision components.

The most diverse materials can be processed in powder form in the 3D screen printing process. Are you interested in 3D mass production processes?

Rely on us – we develop tailor-made solutions for you.

Special Solutions for Printing

Pressure Sensors

Electronic controls, or sensors that are manufactured by means of thick film processes, can be easily processed with our systems, since they are usually flat and transportable.

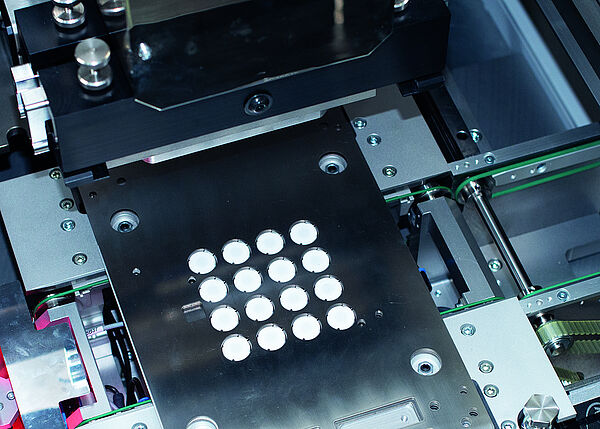

But what does a production process look like in which the starting material is round and only a few centimeters in diameter? A typical picture, for example, for pressure sensors.

The challenges at a glance:

- Print as many parts as possible in one step,

- Tolerances in the individual part, both in diameter and in height, must be compensated before printing.

- Height tolerances (part to part) for multiple pressure must be compensated.

Based on all these specifications, we have developed a production concept especially for round parts that are to be processed using thick-film technology.

Our unique solution:

- A multi-part carrier concept, temperature stable up to 800°C, in order to avoid a rearrangement after the drying process before firing.

- Individual parts alignment (position correction) before printing

- Height tolerance compensation of all parts to each other, uniform offset distance (sieve to surface substrate)

In addition to the printing concept, we offer you the appropriate degree of automation and a coordinated drying concept.

LTCC / HTCC

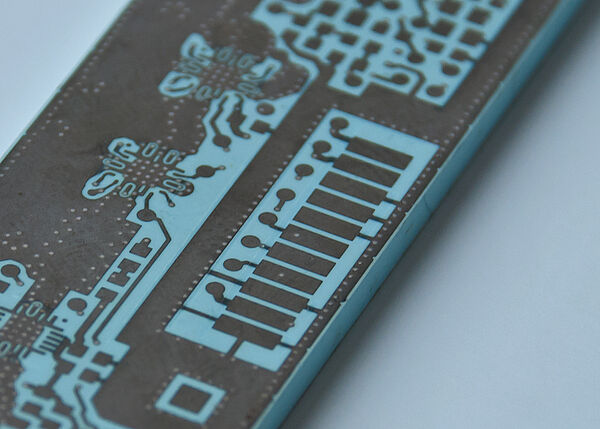

Using our EKRA screen printing system, the metallization is printed layer by layer onto the unfired “green” ceramic foil and then fired. With one of our screen printers you can print Fineline structures up to 30µm. A conductive connection to the individual film layers can be achieved using the Via Fill or Through Hole process.

We realize LTCC/HTCC production as an entry-level variant with the semi-automatic XH STS printing system or as complete LTCC/HTCC line solutions within the ASYS Group.

EKRA LTCC/HTCC Printer Facts:

- Fine-line printing up to 30 µm L/S (depending on paste)

- Established Via filling and Through-hole process

- Process-specific transport systems and pressure nests

- Screen and stencil printing applications with only one system

- Scalable production solution from table system to inline line

- Complete line concepts from a single source

- Highest precision due to measuring system in all axes

- Auto Head squeegee unit for automatic downstop setting