Depaneling

DIVISIO

High-end Depaneling Systems from the Market Leader

Depaneling

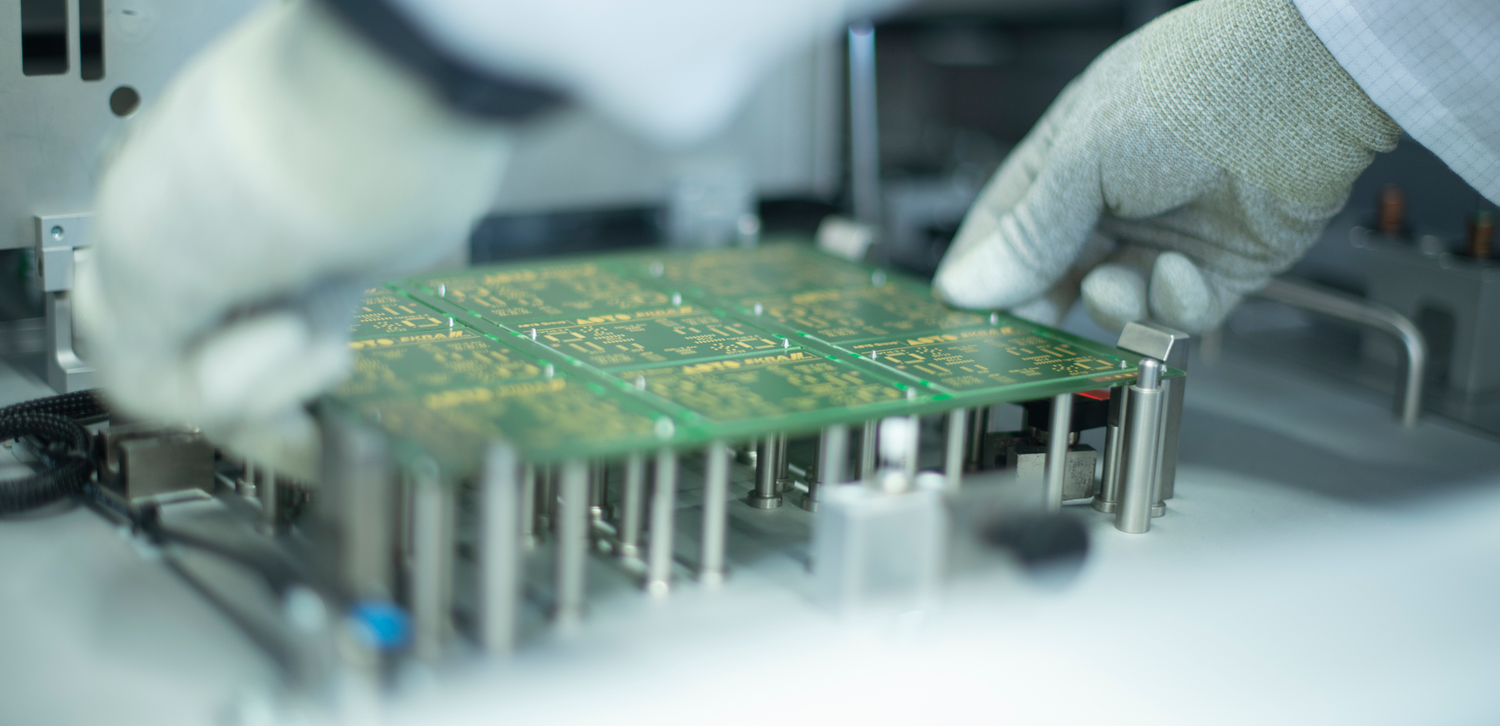

Regardless of material, size or contour – our DIVISIO depaneling systems depanels your printed circuit board from the panel with a precision of 10µm. Whether as an stand alone solution, inline or offline system – we supply a machine that is perfectly oriented to your requirements and your production. In doing so, we rely on proven separation processes: sawing, routing or laser cutting. The 1000th system sold speaks for the success and experience in 20 years of DIVISIO depaneling systems.

Our Highlights:

Focus on Your Advantages

Precision up to 10µm

By using UV lasers you can achieve the highest depaneling accuracy.

Easy to Use

With our SIMPLEX surface operating errors are significantly reduced.

Experience since 20 years

Our experts implement your requirements for the depaneling process.

Technology

Depaneling Processes for Every Application

Thanks to our technological know-how, we solve all the requirements associated with a depaneling process.

-

Sawing

In the DIVISIO 2000, 3000 and 4000 depaneling systems a saw is used. With the help of the saw only straight cuts are made. The PCBs to be processed can be with or without panel edge. The height of the components may be max. 8mm on the saw side. In order to cut panels with larger components, it is possible to saw from above as well as from below.

-

Routing

With the help of the router, more complex panel layouts can be separated with an accuracy of ±100µm. As a rule, the panels are pre-routed and only need to be cut at the web connections. Routing can also be carried out from above and below. The maximum permissible component height is 8mm, partially 15mm. Advantages of this process are: Low stress, good dust performance and routing of free-form contours.

-

Laser

Thanks to the laser, thin and flexible circuit boards can be separated with an accuracy of ±25µm. Different types of laser are used, such as green laser, UV laser and CO2laser. Laser depaneling does not produce dust as with routing or sawing, but only a small amount of suspended matter, which can be effectively extracted. Laser cutting is a contactless and therefore stress-free process.

Semi-Automatic

As a stand-alone solution, our semi-automatic depaneling machines operate with a rotary table. This makes it easy to integrate additional functions such as scanning from below.

In combination with a Cobot, you can additionally increase the productivity and autonomy of the system.

- Small to large batch sizes

- Medium to high product variance

- Manual loading and unloading

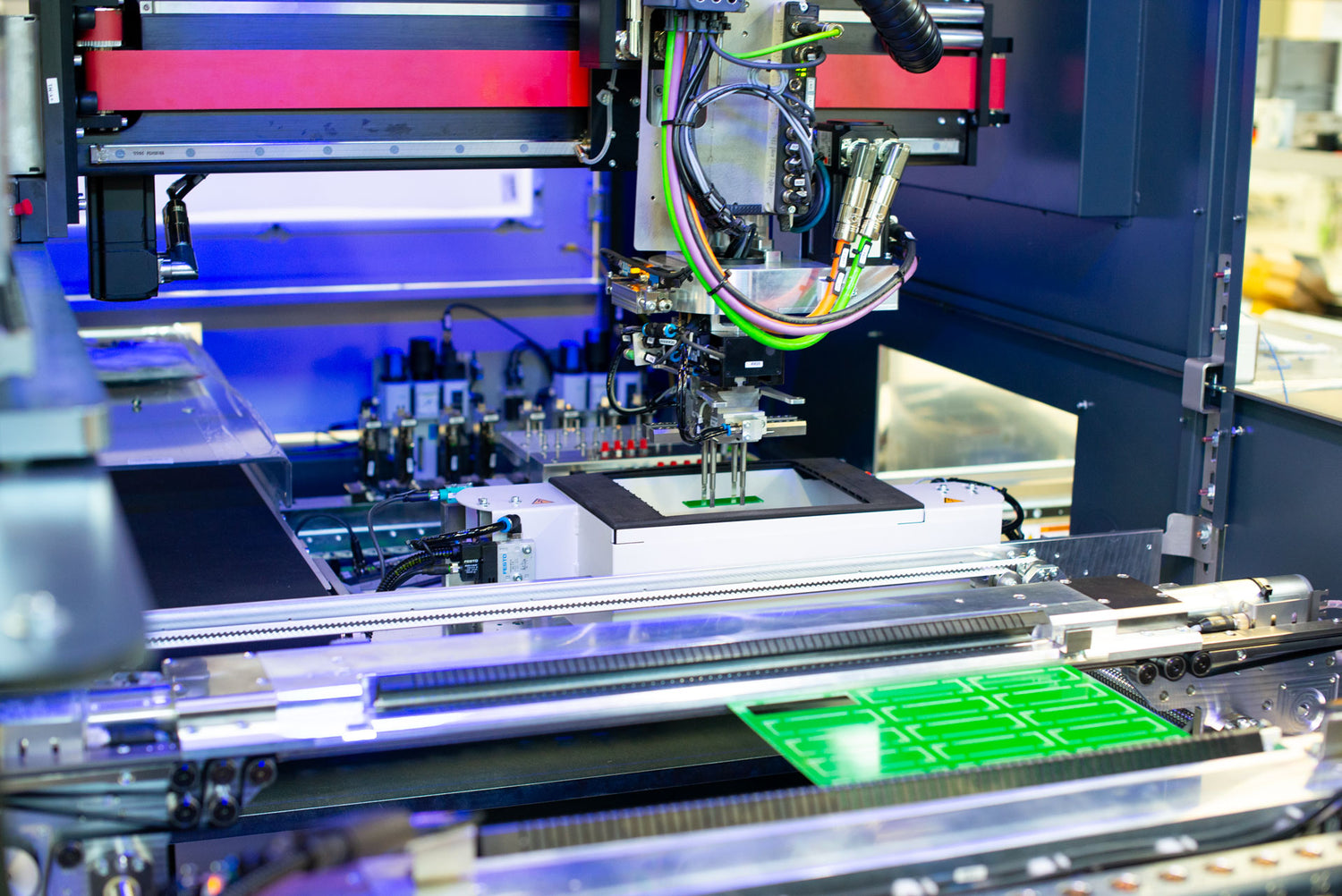

Fully Automatic

You can achieve the highest possible throughput with our flexible high-speed inline depaneling systems. The modular, space-saving design can fulfil all requirements. Do you need different outlet systems, for example? We integrate shuttle, goods carriers, trays, full flat belts or drawers for you.

- Starting with lot size 1

- Highest product variance

Options

Scalable Functions With over 70 options, you can optimally adapt your depaneling system to your production requirements.

-

100% Cut Control

The good parts are only further processed after complete control of all cuts.

-

RGB Light

Use of various control options with one camera, independent of the application.

-

Cleaning with Ionized Air

With this additional cleaning function you significantly increase your product quality.

-

Router Release

To ensure stable process quality, the system detects used routers and automatically replaces them.

High-End Technology

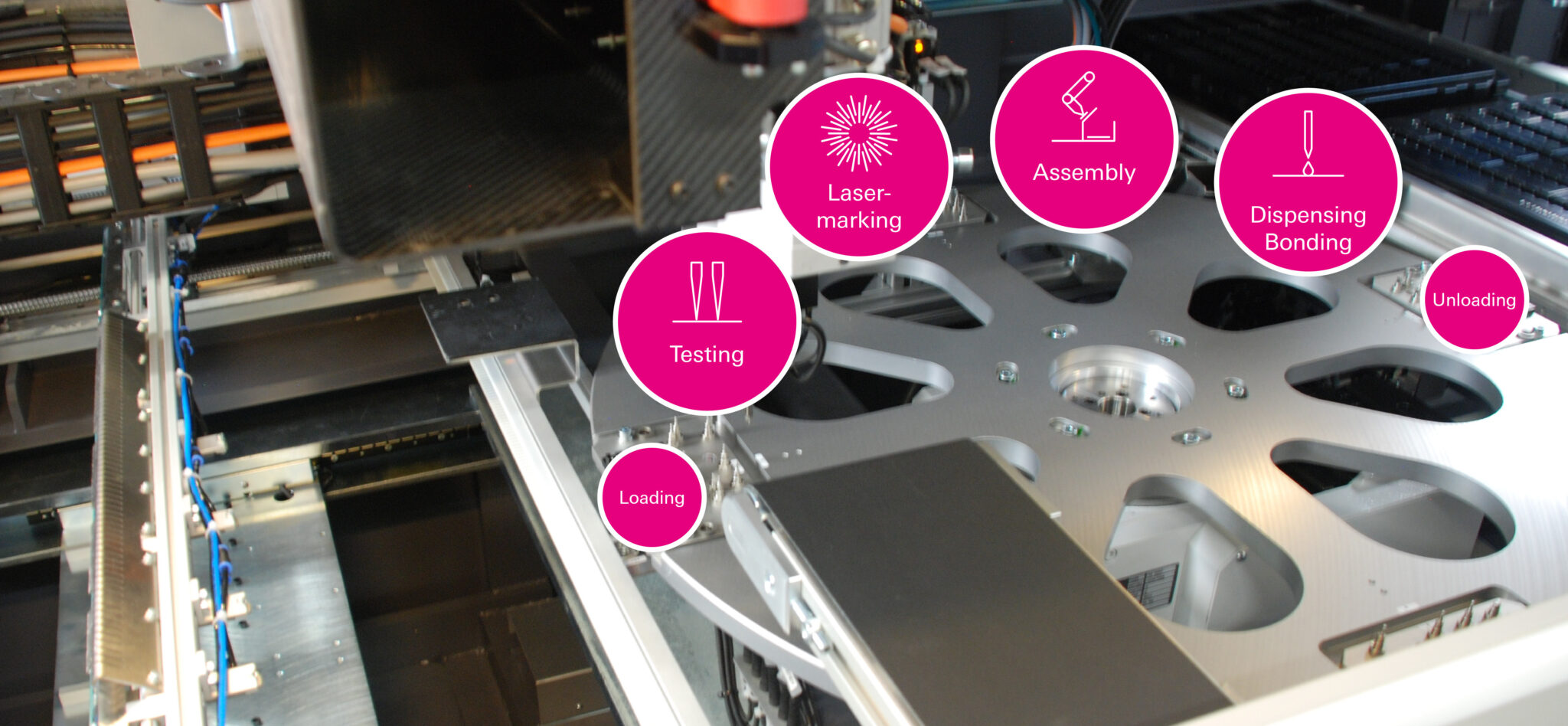

Parallelization of Processes in One System – DIVISIO 6000

Up to 12 stations can be integrated into the DIVISIO 6000 with rotary indexing table. The two carbon axes ensure fast loading and unloading of the table and thus optimum cycle times.

All ASYS Process Systems – One User Interface

Are you looking for simple and intuitive machine operation? Preferably across all process machines within a line? With SIMPLEX User Interface you control all ASYS systems via a touch display using familiar gestures. This minimizes training times and considerably simplifies operating procedures.

- NEW: SIMPLEX Offline-Tool

With this extension you can create a new product – while production is running.