Handling Systems for SMT Lines

VEGO series

Intelligent PCB and magazine handling for highest productivity in the SMT line

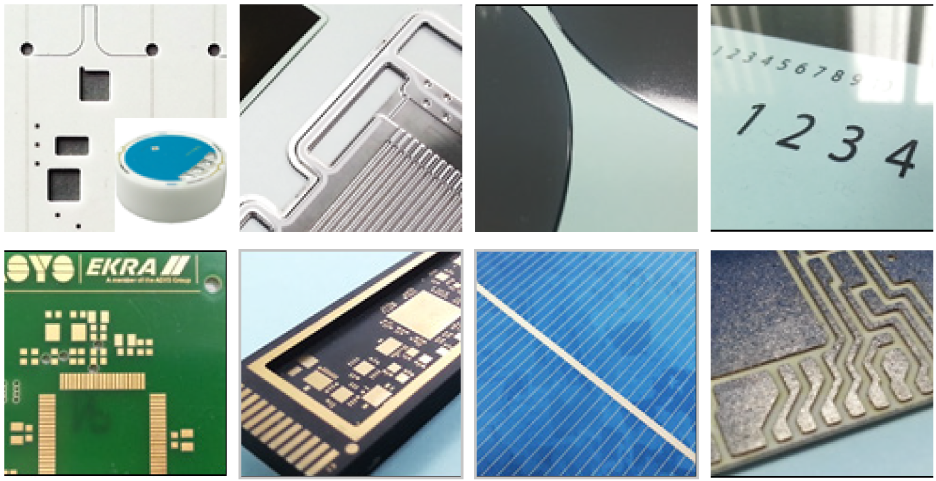

Materials

- Printed circuit boards FR4

- Silicium Wafer

- Plastic / Metal housing

- Goods Carriers

- Ceramics

- Glas

- Component Reels

Connecting Processes Securely

Our handling solutions ensure a continuous and safe material flow

from receiving station to finished product.

SynapticaOS - The Re-Invention of Industrial Software

The new ASYS software platform offers a revolutionary user experience with consumer-like ease of use. This enables intuitive use without the need for extensive training, so that products can be implemented quickly and easily at the customer‘s site. With seamless data availability in all modules and no redundant data maintenance, the platform sustainably increases

the efficiency of your workflows. Synaptica, a comprehensive Manufacturing Operations Management (MOM) system, monitors and controls production machines and proces-

ses in real time and combines MES functionality with advanced solutions for optimizing material logistics and production workflows, based on the Syn OS operating system.

-

ASYS Performance Monitor

Maximum transparency & efficiency for your SMD line

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.Maximum transparency & efficiency for your SMD line. The ASYS Performance Monitor is the perfect analysis tool for monitoring the performance of your SMD line in real time. The automatic calculation and display of the OEE (Overall Equipment Effectiveness) based on performance, availability and quality gives you a comprehensive overview of your production at all times – including bottlenecks and first-pass yield. This solution saves time and ensures greater efficiency on the shopfloor.

- Performance at a glance

- Automatic data collection

- More efficient workflows

-

Task Manager

The smart assistance system for optimi- zed human-machine communication

The Task Manager revolutionizes the operation of production systems and effectively supports your employees. Walking distances are reduced and predictable line downtimes are avoided thanks to early notifications. The remaining running times are automatically calculated by all systems and transmitted in real time – for example, directly to the operator‘s smartwatch. In addition, the Task Manager can be accessed from anywhere, enabling flexible management of work areas across individual lines. The result: an increased OEE and a noticeable reduction in the workload on employees.

- Avoiding downtime

- Flexible working

- Optimal use of resources

-

Smart Messenger

Efficient communication for your production

The Smart Messenger is a multifunctional chat application that considerably simplifies communication between employees in pro- duction. The fast transmission of messages to smartwatches and PCs means that tasks can be assigned more efficiently and immediate support can be requested. Walking distances are reduced, responsibilities are clearly defined and all message threads are stored securely.

- Fast communication

- Increased efficiency

- Flexible support

-

Dash Cam

Real-time monitoring for maximum process reliability

With the Dash Cam function, operators can monitor critical processes in the machine in real time. Thanks to the freely placeable camera and adjustable triggers, live videos can be accessed on tablets or PCs. In the case of faults, recorded video files help to quickly and accurately determine the causes.

- Flexibly positionable camera

- Efficient error analysis

- Real-time monitoring