Viscom

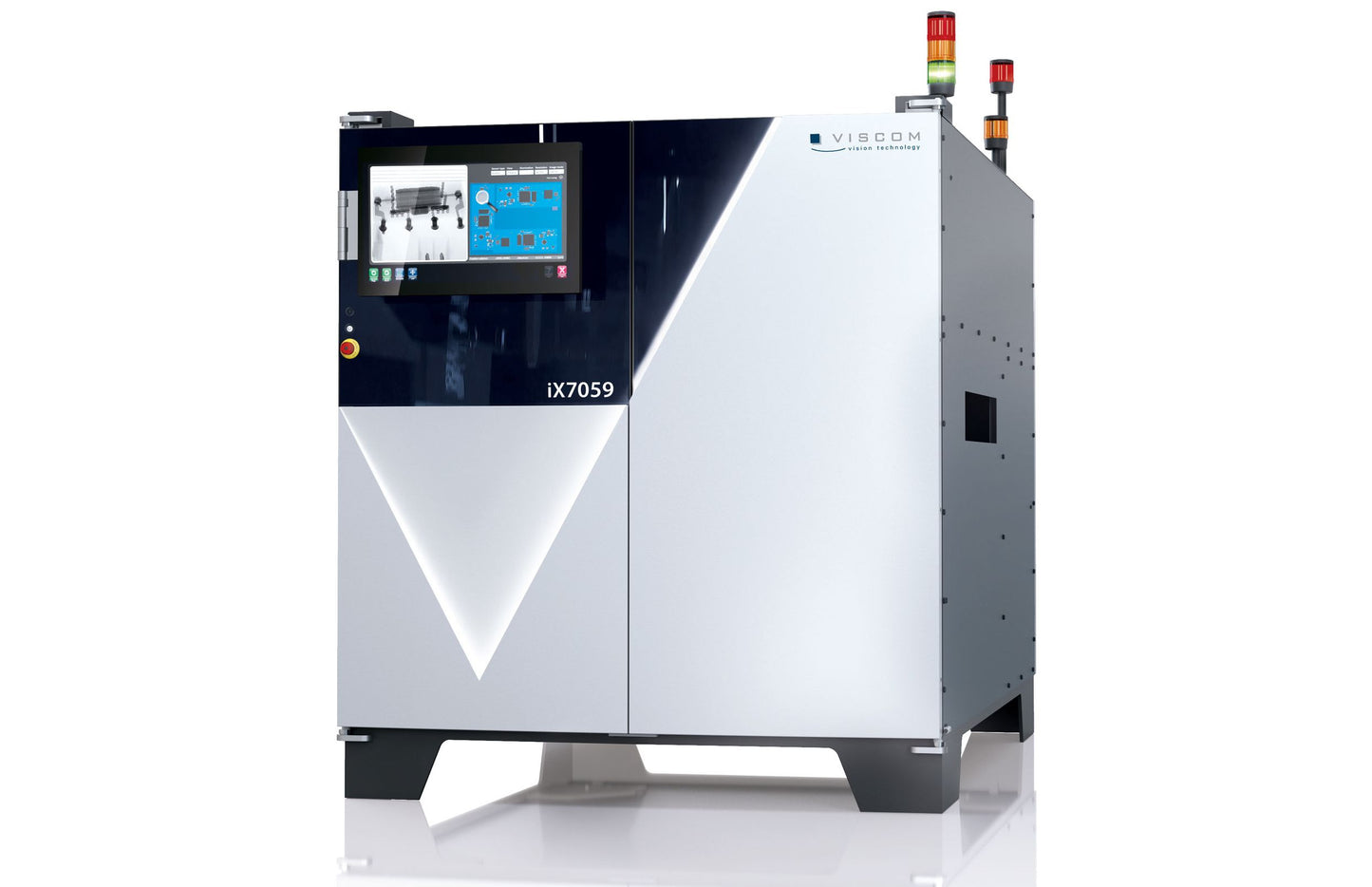

iX7059 Module Inspection – High process efficiency through 3D X-ray and integrated CT

iX7059 Module Inspection – High process efficiency through 3D X-ray and integrated CT

For manufacturers of power semiconductors, such as IGBT modules and SiC chips, compliance with safety and performance requirements is essential. The quality of each individual solder connection of the components ultimately determines whether overheating and thus failure will occur. The new iX7059 Module Inspection offers seamless and reliable quality assurance for this purpose. The fully automatic 3D X-ray system with integrated computed tomography is distinguished by easy-to-classify, accurate layer inspection images and a large inspection scope.

The X-ray system offers flawless handling of frame-based power modules or components on workpiece carriers. The iX7059 Module Inspection is compact and can be easily integrated into a line. There it fulfills - intelligently networked - all smart factory requirements.

Highlights

Highlights

• Precise solder joint inspection for IGBT modules and SIC chips

• Intelligent checking of voids for flawless heat dissipation

• Easy to classify, accurate layer test images

• Fast handling of workpiece carriers and solder frames for maximum throughput

• Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library

• Maximum inspection program optimization through integrated verification

• Additional vertical slices for optimum analyses and dependable verification

• High-quality 3D AXI volume calculation with planar CT

Connectivity

Connectivity

• Global libraries, global calibration: transferability to all systems

• Automated grayscale value calibration for consistent inspection results

• Traceability, statistical process control, offline programming, multiline verification

• Viscom Quality Uplink: effective networking and process optimization

• Interfaces: SMEMA, IPC Hermes Standard (optional)

Inspection

Inspection

Scope of inspection: Twisted, missing or wrong component, hidden blow holes (voids) in surface soldering and THT solder joints

Share