Viscom

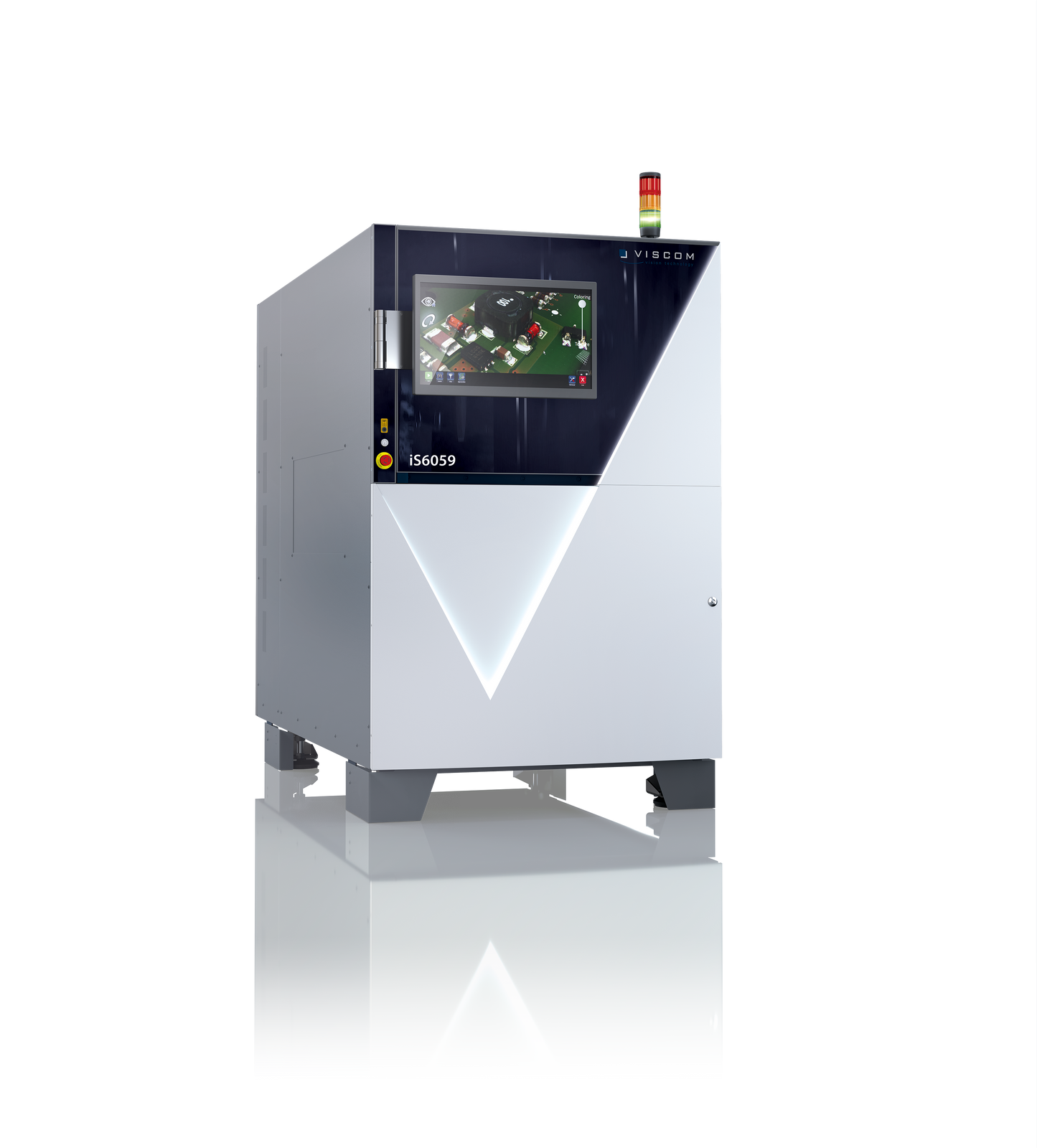

iS6059 Dual Lane Variants – High-Speed System for Dual-Track Production

iS6059 Dual Lane Variants – High-Speed System for Dual-Track Production

The iS6059 Dual Lane Variants Inspection combines the advantages of special high-speed 3D sensor technology with excellent inspection quality and extremely fast inspection speed. The 3D AOI system, which was developed for the economical large-scale production of assemblies, reliably inspects both components and solder joints. Within the manufacturing process, it can be intelligently networked for Industry 4.0 applications.

Highlights

Highlights

• Inspection on two lanes at the same time

• Any options you would get with the single lane equivalents are available here, as well

• Robust system design

• Verified zero defect slippage thanks to integrated verification

• Flexible integration into existing productions

• Improved ergonomic design

Connectivity

Connectivity

• Global libraries, global calibration: transferability to all systems

• Intelligent software add-ons such as integrated verification or Viscom Quality Uplink for effective networking

• Traceability, offline programming, statistical process control

• Communication with MES systems

• Independent real-time image processing with Viscom analysis tools

• High-performance OCR software

optional connection to the digital multi-purpose platform vConnect

Inspection

Inspection

Components: up to 03015 and fine-pitch components

Solder paste, solder joint and assembly control

Defects/defect features: excessive/insufficient solder, missing solder/solder skip, component missing, component offset, wrong component, component damaged, component overpopulated, billboarding, component on back, damaged pin, bent pin, solder bridging/short circuit, tombstoning, lifted lead, soldering defects, nonwetting, contamination, polarity error, rotation, imperfect shape

Optional: free area analysis, color ring analysis, wobble circle error, OCR, blow holes in the solder joint, solder ball/solder sputter

Share